|

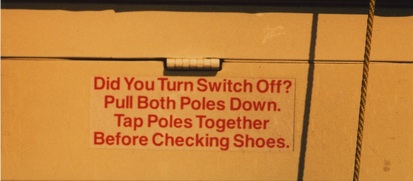

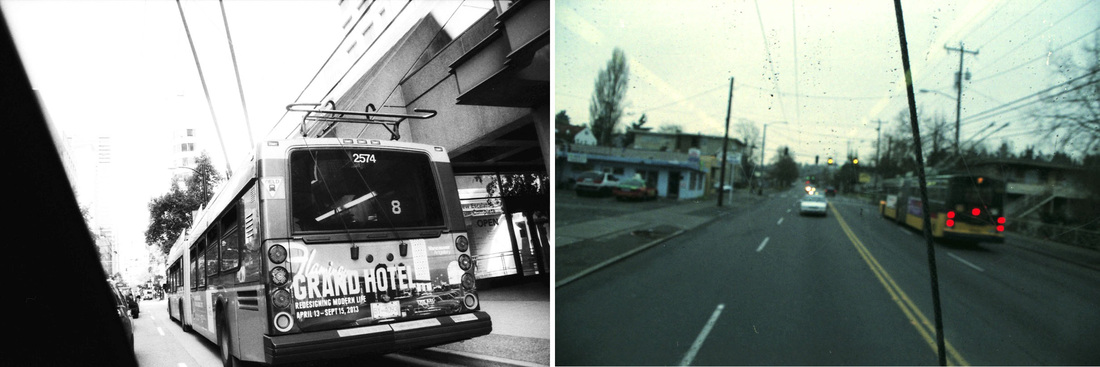

We're sitting at Third and Seneca northbound on the 3, a trolley bus. The passenger in front asks me what my favorite routes are. "I really love doing the trolleys," I respond. "Oh. I've never been on one of those," he says. I point out that he's sitting on one as we speak. There may be more than one person out there who's not entirely sure what a trolley is, or who has perhaps never ridden one. In the interest of sharing my passion for them, and in particular enlightening our far-flung readers, I'm compelled to offer some information on what exactly trolleys are, and why they're so great. A trolley (or trolley bus, trolley coach, or trackless trolley) is a bus powered by connection to overhead wires. Poles extend from above the coach, connecting the bus to its power source. You're familiar with streetcars and light rail, which only need one overhead wire. Why does a trolley need two? Because with rail the electrical circuit is completed by the metal rails upon which the vehicle travels. Trolley buses, with their rubber tires, have no such metal contact point on the ground and thus need two wires to complete the circuit- one a live wire, the other a grounding (dead) wire. The grounding wire is usually the one closest to the sidewalk. A trolley does not contain an engine or transmission, in the traditional senses of those words; there is simply a series of circuit boards inside the coach which direct power to a single gear. The "gas pedal," called a power pedal, is less like a gas pedal than a rheostat. Like a dimmer on a light bulb, you press it to adjust the amount of current being poured into the gear connecting to the rear axle. If you floor it, you're dumping 750 volts into the rear wheels, and you can fly up the steepest hill in the network– that would be the Queen Anne counterbalance, at 18.5 degrees– without a hitch (James Street is a close second, at 18.3 degrees. Why does the bus go so slowly down these hills? Simply for safety. Trolleys and diesels have a speed limit of 10mph downhill on these segments, to avoid plunging into Puget Sound. Buses weigh at least 30,000 pounds, after all!). Trolleys, like public transportation in general, are much more popular outside the US. Only six cities in North America have a trolley system. In order of size, they are: Vancouver, B.C., Frisco, Seattle, Dayton, Philly, and a couple lines in Boston. Hilly cities benefit most from a trolley network. A trolley's torque is dramatically stronger than any conventional diesel engine, and thus they can handle hills much more easily. You're not shifting gears with an internal combustion engine, waiting around to get up speed– rather, you're just shoving current into that single gear, already flying. The agility with which they can take the hills is pretty astonishing, given how accustomed we are to large things in general always moving slowly. It's also worth pointing out that the added torque and better braking lend themselves to superior performance on flat stretches as well. Why are trolley bus brakes better? Trucks and diesel buses are equipped with engine retarders, which slow down the engine when you're coasting, so the regular air brake, called a service brake, doesn't have to do all the work of stopping such a huge vehicle. Trolley buses have "Dynamic Brakes," which are a step up from retarders; they perform the same end function, but rather than slowing down the engine, they actually reverse the thrust of the motor. The generator circuits of the traction motor are loaded down with electrical resistance, resisting the rotation of the generators and thereby slowing down the rotation of the wheels. Reverse thrusters are used to slow down airplanes. Is that better than a normal engine retarder and service brake? Abso-friggin-lutely. It also minimizes wear on friction-based braking elements, allowing the service brakes to last longer.  The poles above the bus are spring-loaded and push up against the overhead using springs and air pressure. A small U-shaped shoe with a carbon contact surface ("carbon insert") is what actually touches the wire. The U-shaped shoe pushes up against the wire, which sits inside the 'U.' Electrical current comes from a network of power plants stationed around the city. These are separate from the city's electrical grid– regular power outages don't affect the service. In the old days the poles were made of steel, as seen below, and they flew off all the time. Now they're made of fiberglass, and can stay on the wire with greater flexibility.  Left, you'll notice the slight bend of the white Keipe Elektrik poles currently in use (two coaches, 4110 and 4236, mysteriously appear to still have steel poles; those two are harder to keep on the wire). The length of the poles and ropes behind the coach give you twelve feet of leeway on either side of the wire to maneuver around traffic. Twelve feet is the width of a regular lane, which means you generally have two lanes to work with, but if the wire is carefully positioned, sometimes you can straddle three lanes if you go slowly. Madison between 8th & 5th and 5th Ave North at Republican are examples of this. You might notice drivers staring intently through their mirror at the back window– they're looking at the ropes outside, trying to get a sense of where the poles are above the coach. If the two ropes are vertical, then you're directly beneath of the wire, of course. When they start slanting, you're drifting away. When the ropes look like they're about to touch in the corner of the back window, that's as far out as you can go. The new trolley buses, arriving in 2015, will not have back windows (unheard of with trolleys), and this will make driving them quite a bit more challenging. What happens when you go too far out from under the wire? The poles pop off. Nothing holds them onto the wire except air pressure. It's amazing to me that they don't pop off all the time, after every bump or turn in the road. A fellow named Max Schiemann developed all this in 1901, and he was one smart cookie. The reason there are ropes connecting the tips of the poles to the back of the coach is twofold: firstly, that way you can actually move the poles about without climbing on top of the coach. Secondly, the ropes supply tension. They are spring-loaded as well, and pull downward, although with only a fraction of the upward pressure the poles possess. This counterbalancing downward pull allows for the minimization of the effects of dips and potholes in the road– things that might otherwise throw the poles off. If one of your poles is coming off too often, you might go out and redo the tension on your ropes, which involves pulling out all the rope and re-winding it around the spring-loaded wheels on the back of the bus.  Ever wondered what the phrase at left, printed on the back of every trolley coach, means? Sadly it's not a reference to tap dancing. They're talking about a scenario where you're wanting to inspect the shoes on top of the pole, because perhaps the pole(s) are coming off even though you're driving properly. They're suggesting that you turn the bus off, and then tap the poles together to discharge any spare electric buildup before getting in close proximity to the shoe. All great ideas, though the likelihood of there being any spare charge in the pole is very small once you turn off the coach. When the poles come off, there is no backup system for moving the vehicle. There is no emergency engine. You'd better hope there's wire your poles can reach, or a slope in the roadway for using gravity to drift back under the wire. Usually there is, but the margin for error is tiny. I find this just fantastic. It's totally exhilarating. It forces me to be in the present, and to concentrate. Sometimes on flat ground with no live wire overhead you'll be at a loss for what to do. The temptation is to simply push the bus a few inches and get back on live wire. A 60-foot Breda trolley is heavy, but trolleys are built to roll... is it possible to push a 55,000 vehicle with your bare hands? I won't tell you if I've done so. I'll simply say that I "haven't," since that would of course be breaking the rules! That's part one. Click here for Part Two!

7 Comments

Vaneza

6/5/2014 04:08:48 am

Wooo, trolley buses! Especially, woo #3 & 4!! :D

Reply

Nathan

6/6/2014 06:08:09 pm

This is pretty much the same sentiment I regularly express to myself over the course of a day of driving the 3/4!

Reply

Nathan

6/6/2014 06:11:38 pm

I too am excited! Metro seems to favor either the "no seats" approach in their new vehicles, a la the front half of a 6000, or a "roomy but still with seating" approach, a la the 6800s and 7000s. I'm hoping for the latter. The 6800 series in particular does a fantastic job of having huge aisles and a spacious interior without sacrificing seating; the two are not mutually exclusive, in my view.

Reply

Tim Ster

8/16/2016 03:33:55 am

I just read this - thanks for the explanation.

Reply

Nathan

8/17/2016 09:18:45 am

Tim-

Reply

Tim Ster

8/18/2016 07:32:26 pm

Thanks for the answer! I work on computers - have for nearly 30 years now - and I often wonder why they change things that are well established, work very well, and are nearly bulletproof. Sounds like someone ought to strap one of your old pole assemblies on the top of the new busses. Leave a Reply. |

Nathan

Archives

July 2024

Categories |

RSS Feed

RSS Feed